Nano Heat-dissipation Coating

Made by synthesizing unique mineral extracts and other special materials into a nanosolution using state-of-the-art nanotechnology; applied on surfaces of materials.

Mechanism for Nano Heat Dissipation Materials

After the material absorbs so much heat as to achieve heat uniformity through thermal conduction, heat starts to dissipate – converting to radiation heat dissipation until thermal equilibrium occurs. Coatings of the material are in a non-linear form, and nano heat dissipation particles are thus stacked to form nano heat dissipation fins, generating a nano specific surface area many times larger than the physical area. Therefore, our materials are able to demonstrate an increased heat dissipation capability.

Feature Description

Ultra-thin coating film

transparent/13~15μm(10-6m)

black/13~15 μm(10-6m)

Insulating

Resist 3000V voltage(black)

Acid/alkali-resistant, anti-salt spray

Acid/alkali-resistant, anti-salt spray

Self-drying/ fast-drying

transparent/1~5minutes

(varies by environment)

black/15~30minutes

Ultra-high temperature-resistant

Temperature forcleavage

800 ℃ (transparent)

1300℃(black)

Strong adhesion

ASTM test

Fastness: 4-5B (3M)

China Metrology Accreditation:Level 0

Product Overview

| Product Name | Technical Parameters | Properties | Application |

|---|---|---|---|

| Nano heat-dissipation coating (transparent) | Fastness: 4-5B (3M) Temperature for cleavage: 800℃ | 1. 15% increase in heat conduction 2. 5-10% increase in heat capacity 3. Acid/alkali-resistant, anti-salt spray, insulating | Surface of transparent materials such as glass and acrylic; surface of metal; optoelectronic industry; “3C products,” etc. |

| Nano heat-dissipation coating (black) | Hardness: 8-9H (ASTM) Fastness: 4-5B (3M) Temperature for cleavage: 1300℃ | 1. 30% increase in heat capacity 2. 30% increase in heat conduction 3. Acid/alkali-resistant, anti-salt spray, insulating | Surface of plastic materials; surface of metal; optoelectronic industry; “3C products,” etc. |

Effects of the Product

1. Power system

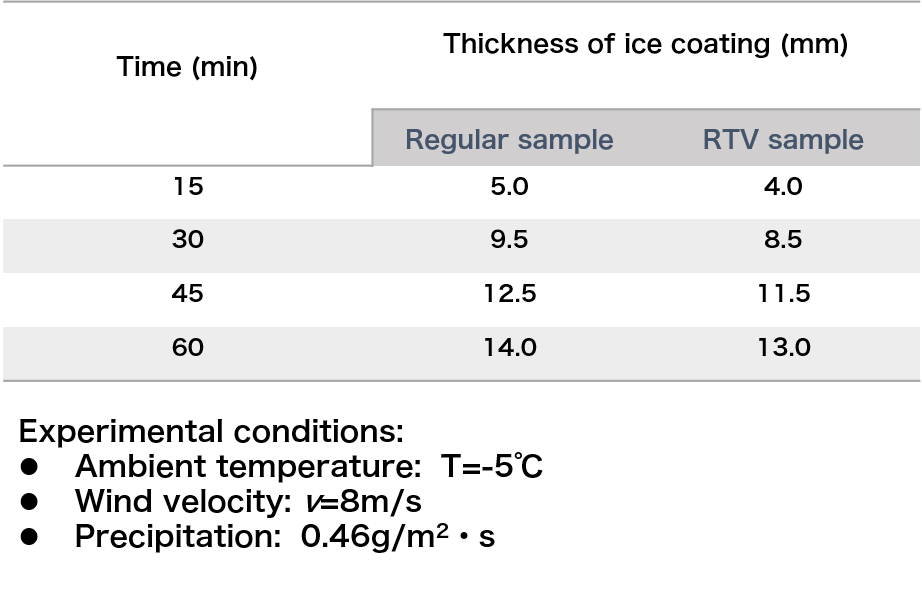

Ice-coating test of a cable

2.Power system

Tested by an hermetic motor with heat-dissipation ventilating fans

| Surface temperature at steady state | Amperage used by the motor | |

|---|---|---|

| Non-treated | 102℃ | 4.08 mA |

| Treated | 89℃ | 3.66 mA |

| Gain | 13% | 11% |

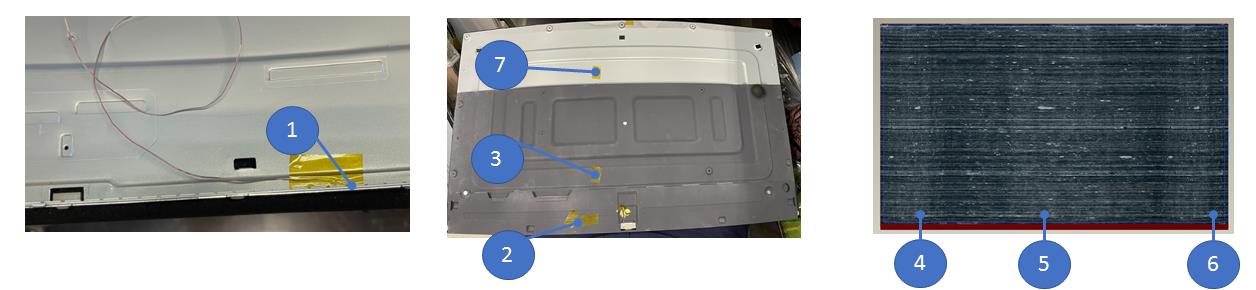

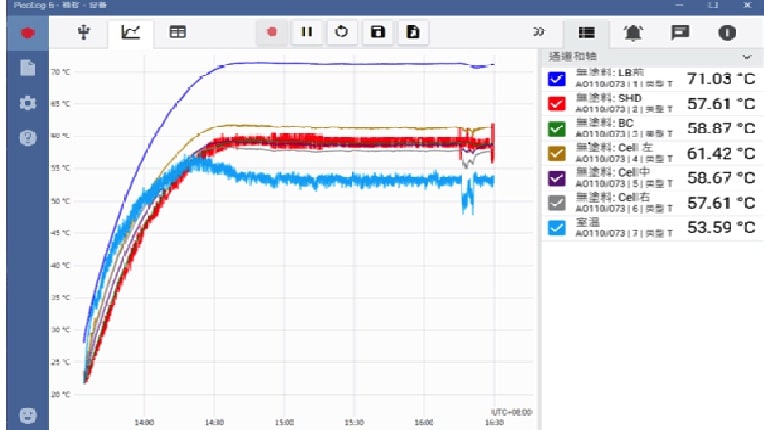

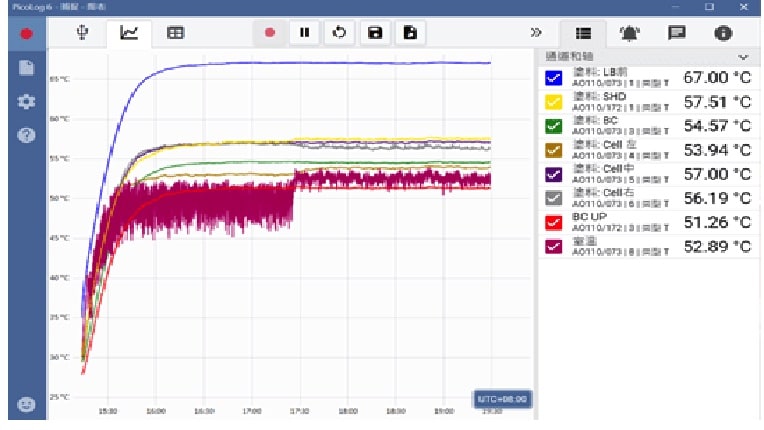

3.Heat dissipation of a display (backlight module)

Solving LCD module overheating caused by LED heat sources

32” curved LCD

| BC Material | BLU measuring points of the non-spray coated panel | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | Ambient

Temperature |

Remark | |

| SECC(spray coated) | 67 | 57.51 | 54.57 | 53.94 | 57 | 56.19 | 51.26 | 52.89 | Ambient temperature:50,

Power consumption: 21.8W |

| Non-spray coated | 71.03 | 57.61 | 58.87 | 61.42 | 58.67 | 57.61 | 53.59 | Ambient temperature: 50,

Power consumption: 21.8W |

|

Temperature curve of the tested 32” curved LCD

Test results

1.Groove of the LED tube light (in front of LB)

2.PCB and cover of the driver IC chip (SHD)

3.Backlight plate center (BC)

4. 5. 6. are respectively located on the left, in the middle, and on the right of the LCD module. (Cells left, middle, right)

Potential temperature of the LED tube light drops to 67°C from 71.03°C.

The average temperature of the three points of the LCD module (Cell) drops by 3.5°C.

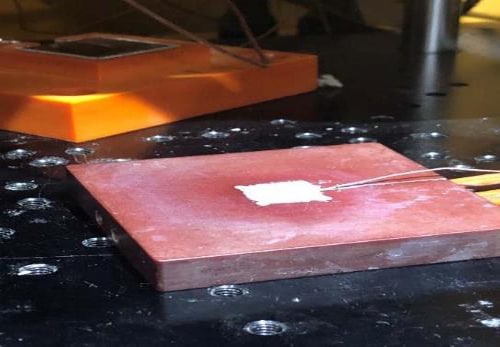

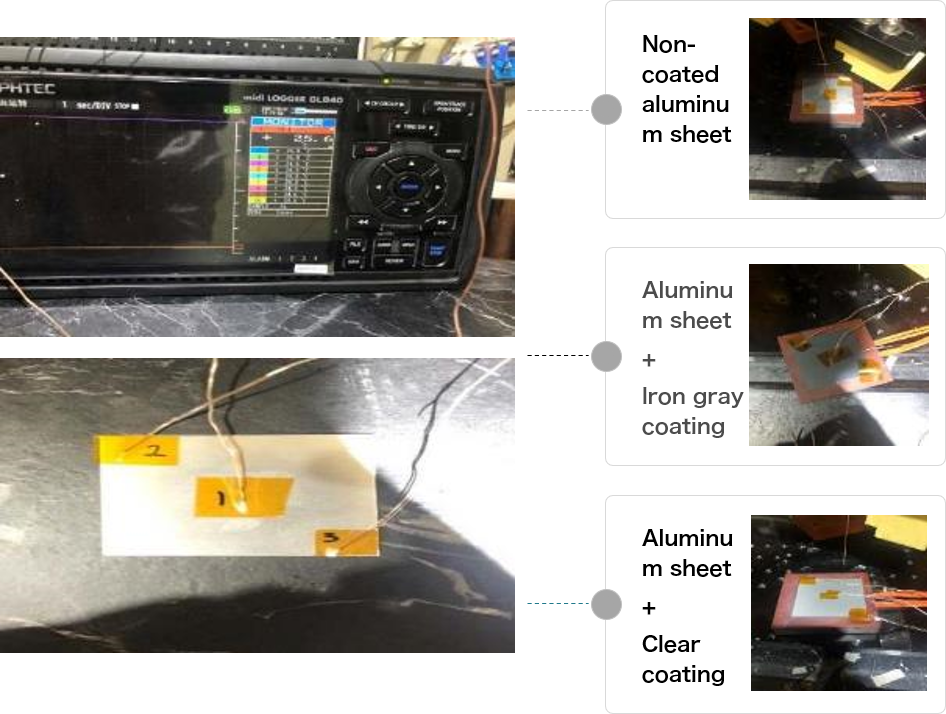

4.Nano heat-dissipation coating apparatus testing

Aluminum sheet: 50mmL X 50mmW X 1.0mmT

Test condition: natural convection

Test duration: 1 hr (put three sheets to test, and then take the average)

Ambient Temperature:26℃

Test equipment:

Heat source: Dummy Pad+ Thermal Grease (K=8)

| No. | Center | Upper left | Lower right | 1cm above the center | Heat Source | Thermal resistance (℃/W) |

|---|---|---|---|---|---|---|

| NON-COATED | 68.8℃ | 64.8℃ | 64.9℃ | 30.7℃ | 70.7℃ | 7.934 |

| IRON GRAY | 64.4℃ | 59.1℃ | 58.0℃ | 36.9℃ | 68.1℃ | 6.189 |

| CLEAR | 63.2℃ | 64.9℃ | 62.6℃ | 34.3℃ | 70.3℃ | 7.141 |

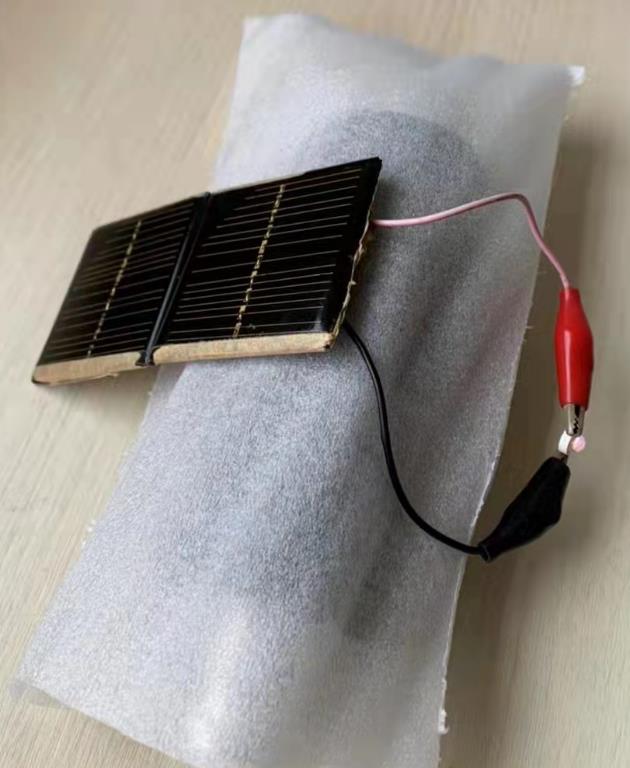

5. Increasing transmittance of solar panels

2021/10/22 AM:9:00

Rainy (cloudy) 2W solar panel

Experimental version (LED lit up)-coated with the clear coating

2021/10/22 AM:9:00

Rainy (cloudy) 2W solar panel

Experimental version (LED unlit)-not coated with the clear coating