A Material for Surface Treatment of Substrates

Roughening-free Adhesive

Properties of the adhesive:

Sprayed on a substrate to enhance lamination of materials such as photoresist or sputtering thereon, further improving process yield and raising profits.

Product benefits

A wider range of substrate choice

Simple equipment

Mitigates side-etching

Roughening of substrates not required

Suited for high-resolution process

Achievements

- Manufacturing process validated by the world’s top FMM manufacturers

- Better copper-clad IP tape test results than the average of the industry

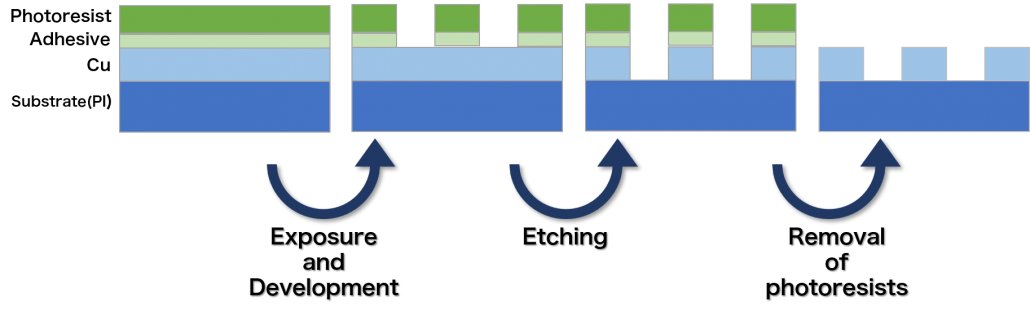

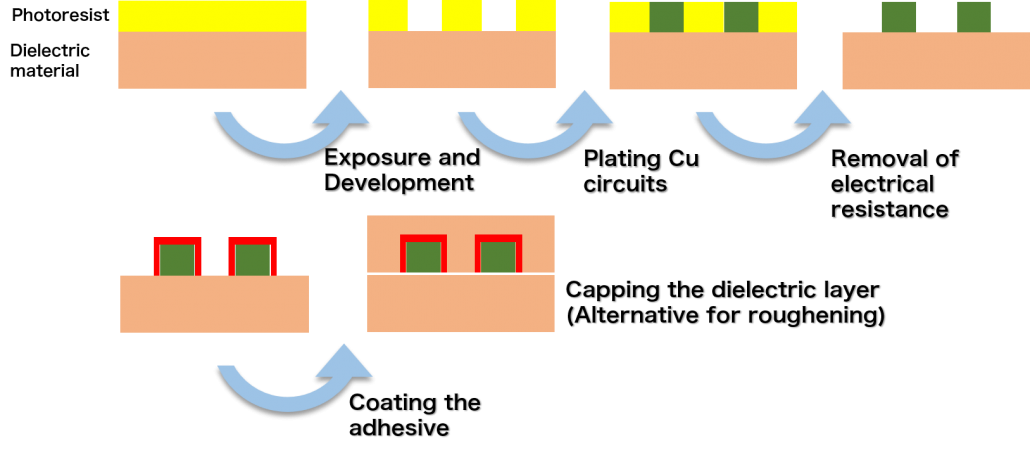

Operation procedure

1. Substrate cleaning (Degreasing)

2. Washing

3. Coating the adhesive

4. Washing

5. Hot air knife-drying

6. Laminating dry films (photoresist)

Effects of the Product

Objectives

Sprayed on a substrate to enhance lamination of materials such as photoresist or sputtering thereon,

which further improves process yield and increases profits.

Benefits

- Widens the range of substrate choice

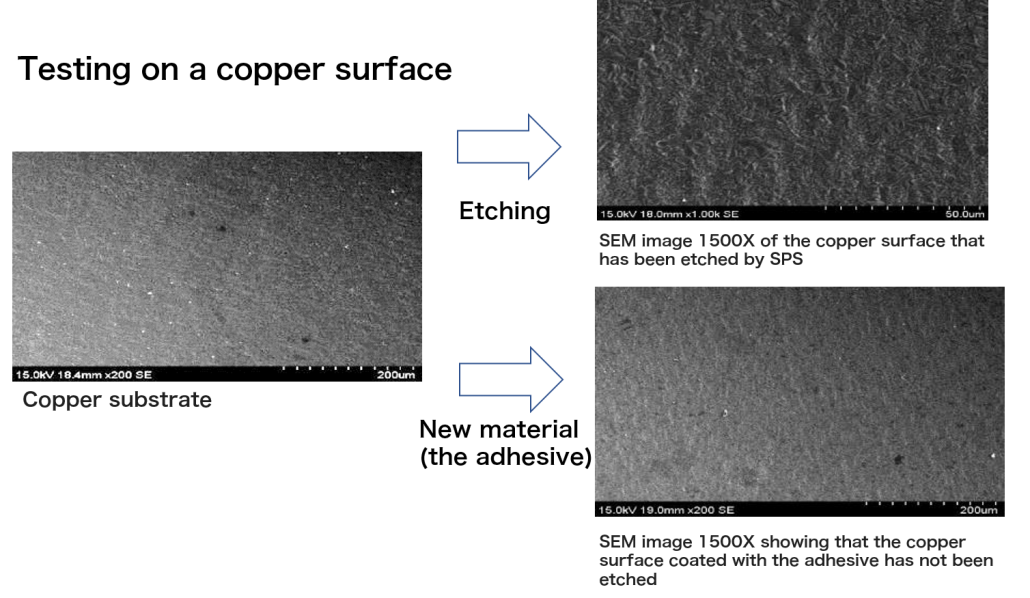

- Roughening of substrates not required

- Simple equipment

- Suited for high-resolution process

- Mitigates side-etching

Achievements

Manufacturing process validated by the world’s top three FMM manufacturers.

Better copper-clad PI tape test results than the average of the industry.

Practical Testing

PI Copper-clad/3M610 Tape

Test conditions: the bottom layer is PI, the middle layer is nichrome (100nm), and the upper layer is copper (300nm)

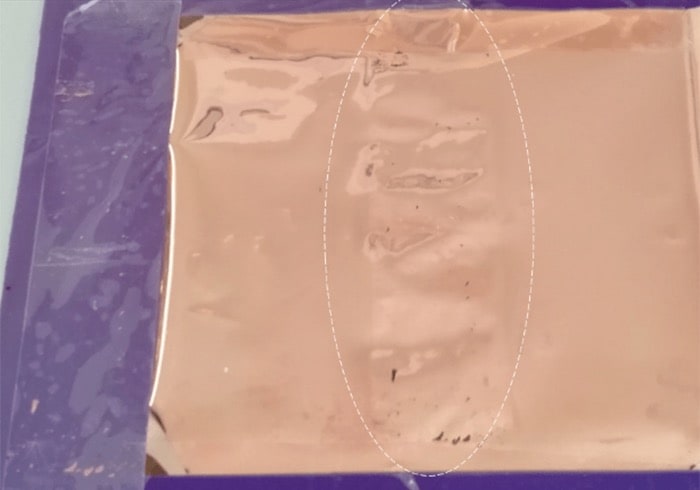

Flotation Improvement

Flotation rate decreases; yield increases by 30%

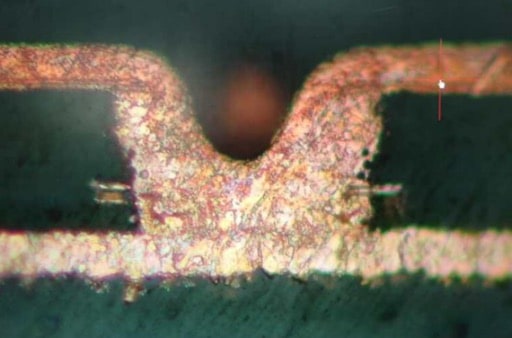

Roughening

Substrate and Electroplated Copper

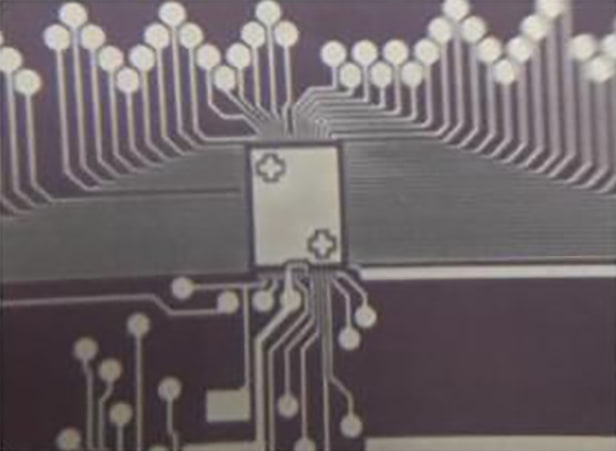

Fine Metal Mask FMM

Side-etching significantly reduced

Capacitance

No gas generated under sintering at a high temperature